Software possibilities

The LBR5 optimization software for ship and offshore structures, and also waterway infrastructures (lock gates, ...) was conceived and developed.

The aim is to add to the traditional design tools used during the preliminary project, a tool:

- analysis of the behavior of entire structure, a cargo hold or at least a series of mid-ship sections,

- explicit relationships of all limit states related to the structure (as serviceability and ultimate limit states) through a rational analysis of the structure. Rational analysis means coherent and consistent methods of calculation based on physics, solid mechanics, strength of materials, ... and differs from empirical and parametric formulations;

- at the stage of preliminary design, scantling optimization (size) of components of the structure;

- integration construction costs and manufacturing process optimization via a cost objective function.

It is primarily in the draft that the optimization module shows its potential. Indeed, during the early stages of the project and the flexibility and speed of modeling methods provide valuable assistance.

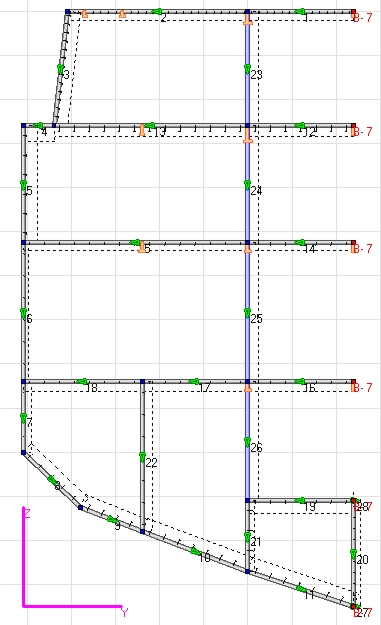

(1) exemple d'une coupe au maître

LBR5, an optimization tool for the preliminary project

The LBR-5 model (Software (logciel) Bordages Raid) is an integrated tool for analysis and optimization of orthotropic structures and sea water. This tool has a feature to allow the opportunity during the preliminary project design optimization, that is to say during the initial phase of the design.

No initial preliminary design is required. The engineer can start directly by automatic search of optimum design. It is not necessary that the original dimensions correspond to an admissible solution. The role of the LBR-5 model is first to seek an acceptable solution (which complies with all restrictions imposed) and then offer each iteration a better solution that continues to respect these restrictions. Finally, the optimal solution is obtained within 10 to 15 iterations and that, whatever the number of design variables (XI) and restrictions (C (XI) <= Cmax).

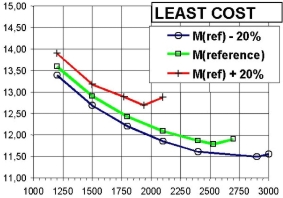

The optimum design obtained is the minimum cost of construction (Fig. 2 and 3) which is defined as the objective function F (XI). Design variables (XI), number 9 for each element (stiffened panels) correspond to the thickness of the metal plating, the entredistance and dimensions of the longitudinal reinforcements (4 variables) and the entredistance and dimensions transverse frames (4 variables). The elements are orthotropic stiffened panels that make up the structure. These may be signs of very large size.

LBR-5 provides thus:

- Looking for a set of N design variables: XI (i), i = 1 to N,

- Which minimizes the objective cost function: MIN [F (XI)]

- Which follows a group of M restrictions: Cj (XI) <= Cj (max), j = 1, M.

|

|

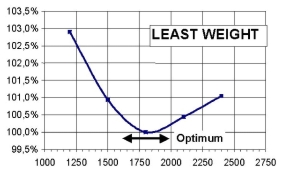

| (2) Optimal spacing of frames (pairs) for cost optimization | (3) Optimal spacing of frames (pairs) for optimized weight |

Three modules

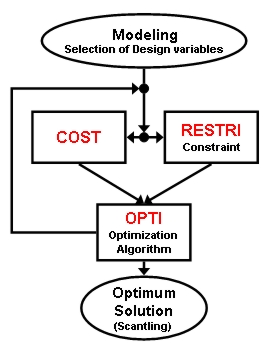

LBR-5 is designed under the concept of Optimization Oriented Modules. Thus the model LBR-5 is based on the 3 core modules include: OPTI - module containing the mathematical algorithm optimization; RESTRI - module restrictions and COST - module of the objective function cost of construction (Fig. 4).

(4) Organigramme LBR-5

The mathematical optimization algorithm chosen based on a dual approach coupled with a convex linearization (OPTI module). The convex linearization can replace the original problem consisting of nonlinear equations implied by a series of problems consisting of linear equations and explicit (iterative approach). At each iteration, the linear problem is explicit and constrained replaced by a virtually unconstrained problem through the dual approach (Lagrange multipliers).

The elastic analysis of the entire structure is made using the software planks stiffened (Module Analysis LBR5). This module is based on the analytical solution of differential equations of orthotropic cylindrical shells and developments in Fourier series. Its use allows an analytical calculation of sensitivities (first derivatives of the restrictions and the objective function with respect to design variables).

The restriction (RESTRI module) decompose in the technological limitations, geometric and structural. Particular attention is given to the ultimate strength of stiffened panels and tablets of the ultimate strength of the overall structure. For the choice of restrictions, restrictions of a bank is available to the user. Each restriction is associated code (1 to 300). The user selects easily restrictions it wishes to impose structure (maximum stress, strain, ultimate strength, slenderness, ...) by associating with each element a set of codes.

An objective function is necessary to process optimization. The COST module, which allows direct calculation of construction cost based on the design variables, has been retained and can perform a structural optimization based on construction costs.

Scope

The field of software applications LBR-5 on the door lock (door lock floating sea), FSO barges, tankers, cruise ships, passenger ships (monohulls and multihulls).