EOL PROJECT

« Software development for structural optimization of onshore windmills »

This research results from the collaboration between ANAST & ArcelorMittal Research Center Liège.

Framework of the research

Both in Europe and worldwide, the production of wind energy has been developed rapidly. During the past 10 years, the production capacity of wind power installed has increased from 1.7GW in 1990 to 100GW in December 2008. In 2008, total investment in wind power was over 36.5 billion euros, with 11 billion invested in the European Union.

Steel is the most used material for the construction of windmills. For classical tours (about 80 m high), very conservative technical requirements and old design involve the use of common steels for which the competition between manufacturers is hard. For towers higher than 100 m, concrete becomes technologically and economically more interesting than steel.

tours de grandes hauteurs, le matériau acier subit la concurrence du béton car celui-ci devient technologiquement intéressant au-delà de 100m.

Characteristics and objectives of the EOL project

From 2006 to 2009, ANAST in collaboration with ArcelorMittal Research Center Liège has developed a software called EOL for structural optimization of onshore wind towers. The goal of this project was to identify solutions that minimize the production costs or the weight of the steel structure. The benefits of using high strength steel for the building has also been studied in the framework of EOL project.

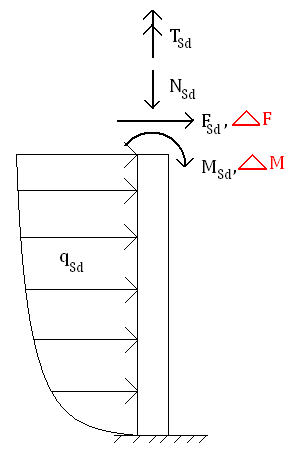

The search of an optimal structural design for onshore windmills envisaged a series of design variables such as diameter and thickness of steel plates, steel grade and the presence of stiffeners in the structure. This optimization procedure should be invoked at the preliminary design stage of the wind turbine structure. For this reason, only loads applied in the plane of the wind direction were considered (see Figure 1).

Figure 1 – 2D loading diagram for an onshore windmill.

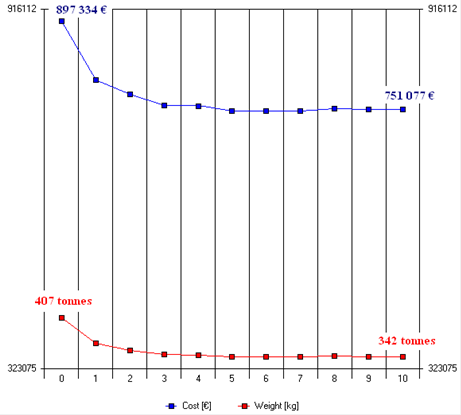

An example of weight optimization for an onshore wind tower of 78 m high made of steel S460 is given below.

Weight and cost evolution during the optimization procedure |

General dimensions of the tower after the optimization procedure |

||

|

Total height |

78m |

|

Characteristics at the base of the tower |

Diameter |

8,8m |

|

Thickness |

27mm |

||

Characteristics at the top of the tower |

Diameter |

5.4m |

|

Thickness |

20mm |

||

WINDSTEEL PROJECT

« Development and optimization of high strength steel solutions for offshore windmills »

This research results again from the collaboration between ANAST & ArcelorMittal Research Center Liège, with Région Wallonne as 3rd partner.

Framework of the research

In Europe, the overcrowding of the territory and the huge potential of offshore wind power force more and more countries to install their turbines offshore. However, risks and uncertainties related to the marine environment remain numerous and are often sufficient to discourage investment in the sector of offshore wind.

Different designs are now available for the installation of fixed offshore wind farms:

- Concrete gravity foundations (e.g. offshore wind farm in Thornton Bank, Oostende)

- Monopile foundations made of steel (see Figure 2) or concrete;

- Jacket foundations.

- Tripod and quadripod foundations.

- Foundations with three piers.

Among these solutions, monopile offshore windmills made of steel are a very good technico-economic compromise for shallow sites.

Figure 2 – Monopile offshore windmills made of steel in Zeebrugge

Figure 2 – Monopile offshore windmills made of steel in Zeebrugge

Characteristics and objectives of the Windsteel project

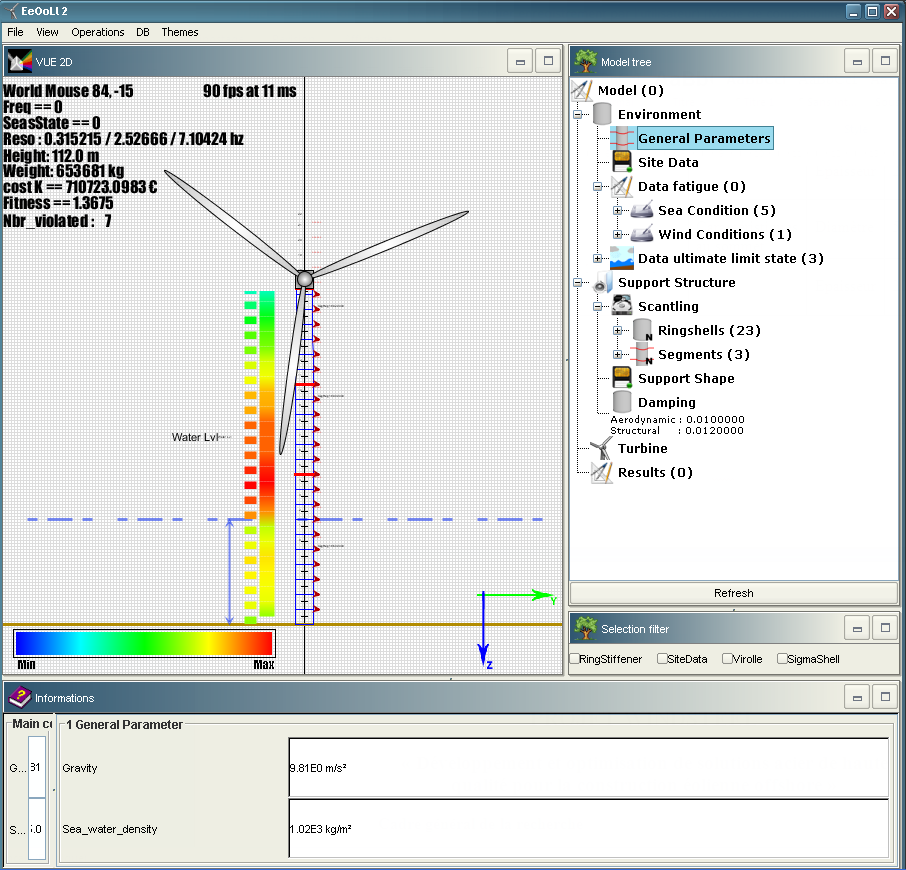

In the continuity of the researches carried out for the EOL project, the Windsteel project aims to develop a design and optimization tool called EOL OS for steel monopile offshore wind turbines (see Figure 3).

The design procedure implemented in the software is mainly based on a calculation of dynamic loads of wind and wave and on the verification of the different strength criteria prescribed by Det Norsk Veritas and Germanischer Lloyd standards.

The optimizer part of EOL OS is based on a "genetic" algorithm able to select windmills structures satisfying the resistance criteria and having in the same time minimum weight or production cost.

Figure 3 – Screen shot of the EOL OS software

Software development for structural optimization of onshore windmills